Previous Next

Water cooled chillers absorb heat from process water and transfer it to a separate water source such as a cooling tower, river, pond, etc. Industrial water chillers are generally used for large capacity applications, where the heat generated by an air cooled water chiller creates a problem. They are also considered when a cooling tower is already in place, or where the customer requires optimum efficiency of power consumption.Water cooled chillers require condenser water treatment to eliminate mineral buildup. Mineral deposits create poor heat transfer situations, which reduce the efficiency of the unit.

Air cooled chillers absorb heat from process water, and the heat is then transferred to the air around the chilled water unit. This type of chilled water system is generally used in applications where the additional heat it discharges is not a factor. In fact, it’s often practical to use the excess heat to warm a plant during the winter, thus providing additional cost savings.

Air cooled chillers require less maintenance than water-cooled units, and they eliminate the need for a cooling tower and condenser water pump. However, since a wet surface will transfer heat better than a dry surface, an air-cooled chilled water system will tend to consume approximately 10% more power than a water-cooled unit.

.jpg)

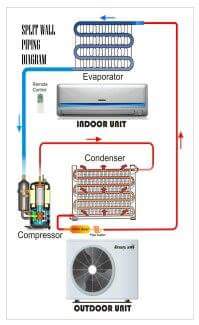

In the direct expansion or DX types of air central conditioning plants the air used for cooling space is directly chilled by the refrigerant in the cooling coil of the air handling unit. Since the air is cooled directly by the refrigerant the cooling efficiency of the DX plants is higher. However, it is not always feasible to carry the refrigerant piping to the large distances hence, direct expansion or the DX type of central air conditioning system is usually used for cooling the small buildings or the rooms on the single floor.

DX stands for "Direct expansion," the most common type of air conditioning system used in homes. Direct expansion HVAC systems use the same coil system to expand the refrigerant and cool the air. A valve is used to stop the compressed gas before it reaches the cooling coil, then relieves some of its pressure, allowing it to expand and cool. The cool gas is then released into the coil while outside air is run past the coil to cool it down.

The refrigerant is compressed and expanded to control how much heat it holds. When the gas is expanded and pressure is relieved through the direct expansion valve, the gas becomes quickly cold, colder than the air in the building. This in turn cools down the coil. When the gas is warmed again, it become more liquid in nature and is cycled back through the system, compressed and evaporated again until the air is cooled enough.

The air is channelled by vents to the HVAC unit itself, where it is run past the cooling coils. Heat always follows the path of least resistance, so when it is exposed to the cold coils (through which the refrigerant is moving as well) it leaves the air and is channeled into the coils until the two are equalized, leaving the air noticeably colder.

Package Air conditioners of 5.0, 7.5, 8.3 11.0 and 16.5 Ton capacities are extensively used for varied applications. These are available only air cooled versions. Made with two equal independent circuits for capacity and redundancy. Capable of developing up to 60 mm WG of net external static pressure, to overcome resistance through Micron filters for fine filtration of air.

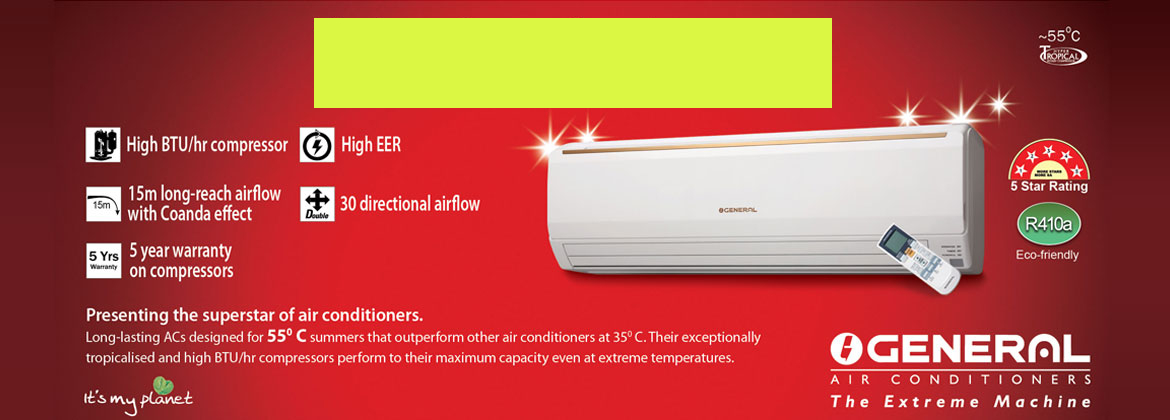

It your office, or your home, now you can expect the very best cooling with Star rated range of Hi-Wall Split ACs. Certified to be 2 Star, 3 Star and 5 Star rated by the BEE (Bureau of Energy Efficiency), these Split ACs offer you the dual advantage of high performance cooling without high electricity bills. What's more, the design ensures your modern interior décor perfectly.

Star rated Hi-Wall Splits also offer you the added advantage of pure, germ-free and allergen-free air. That's because they come equipped with hi-tech filters that block dust, mould, bacteria, viruses and other allergy causing agents.

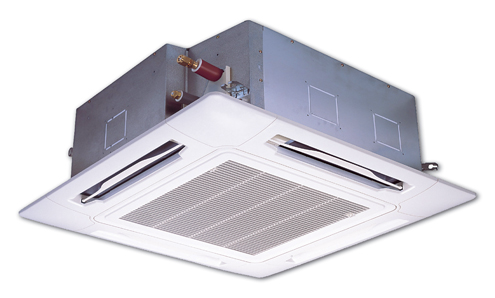

Cassette air conditioners not only look contemporary, but are also extremely quiet and installation friendly. They blend beautifully with stylish interiors by virtue of their excellent looks, fit and finish. Their compactness and ability to distribute cool air uniformly in four directions without ducting make them an ideal choice where it is not practical to have a ducts for air flow (due to structural constraints such as low cross beams).

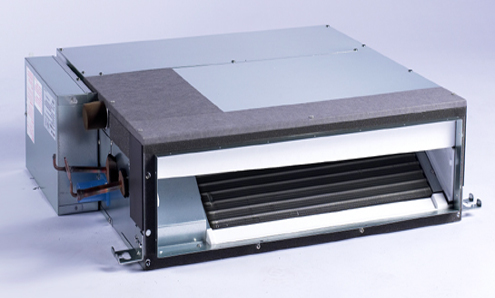

Ideally suited for offices, Conference rooms, Apartments, Hotels, Restaurants, Shops, Basements, High Security Areas, Bank Vaults or wherever a conventional air conditioner cannot be fitted or cool efficiently and economically. Ductable Split System Air conditioner is designed for problem areas. That is true because the components are installed separately. The sleek indoor cooling unit is installed within the room to be air conditioned and the condensing unit is located outside. The external dimensions are kept to a minimum, enabling transportation of the units economical, safe and simple. Flanges are provided for easy mounting to the ceiling of a room in a horizontal position. Pre drilled duct flanges are provided for supply air openings to minimize duct connection work

A vertical air conditioning solution for large commercial spaces such as open-layout offices, showrooms and banks particularly when you need it in no time.

Precision air conditioners are used to ensure precise control of temperature, humidity and indoor air conditions thus ensuring optimum working environment in IT centers, apparatus rooms, reference chambers and server rooms. precision air conditioners hardware implementation may vary widely: from single-module units of 0.3kW power to the modular systems with the cooling capacity of up to 280 kW, which can be used for the wide range of purposes.

Precision Air conditioners are ideal cooling solutions wherever continuous, round-the-clock, precise control of temperature, humidity and filtered air is desired, Modular in design,

Highly energy-efficient and designed for 24x7 operations, using an open-architecture control protocol, these air conditioners offer very low cost of ownership and subsequent up gradation.

VRF systems are ideal for variable load applications, as their design is based on inverter technology. This adapts the speed of the variable-speed compressor to the varying thermal loads in a building. The Pulse Modulating Valve (PMV) in each unit controls the exact amount of refrigerant to be injected into each indoor unit.

In addition, two temperature sensors and a pressure sensor permanently control the amount of superheat, ensuring a safe operation. The pressure sensor also helps to balance the refrigerant flow. With VRF outdoor units, indoor units, Y-joints, headers and controls are all part of a single package.

The Cold Room Concept:- A form of refrigerated storage facility attached to application like Super Market, Catering Establishment etc. Each of these Cold Rooms consist of precisely engineered components that are designed keeping in mind durability and reliability during usage

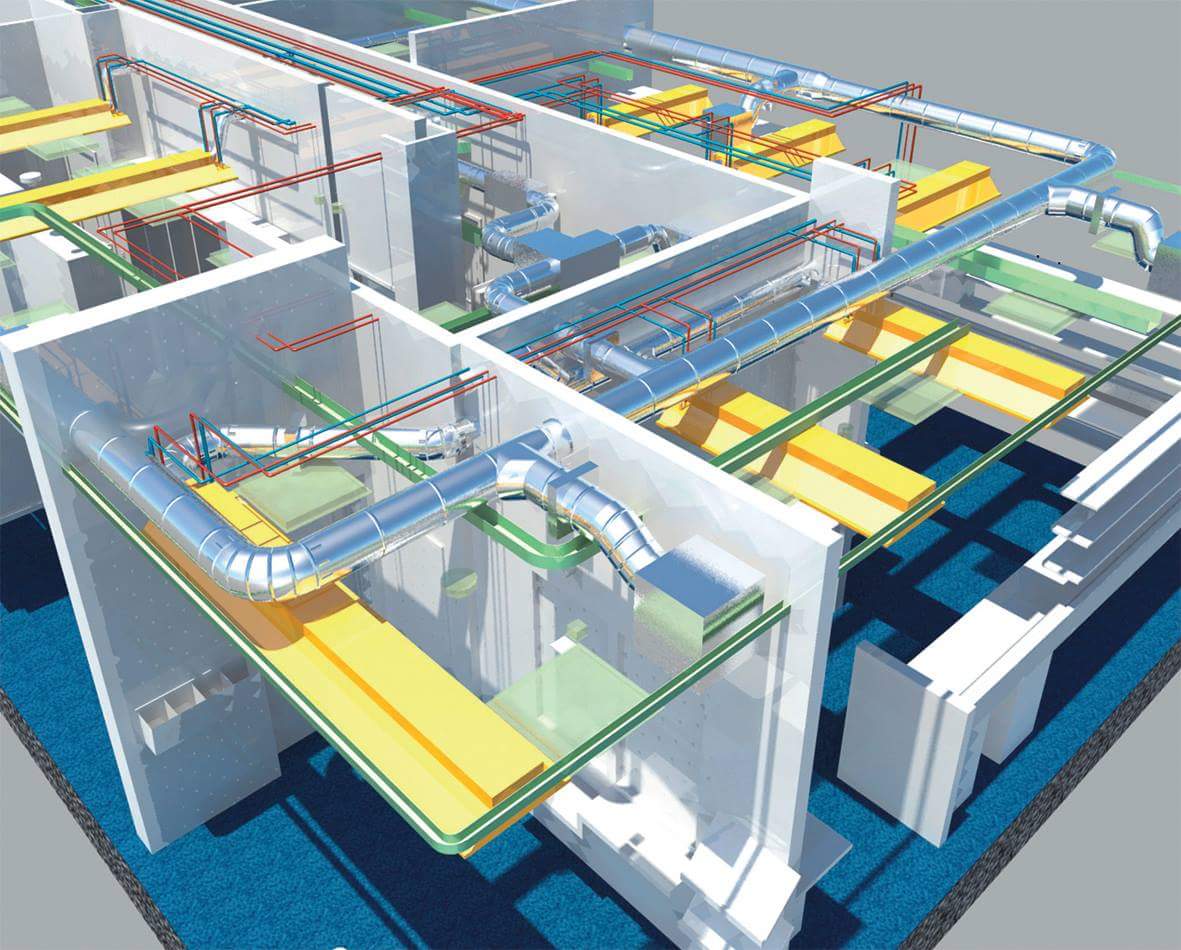

It is an already established practice now in commercial vertical that the builder constructs the complete structure with basic HVAC requirements. The building with Chillers and pipeline connecting the Air Handling Units (AHUs), located in respective AHU rooms of various floors. These AHUs are designed to deliver a pre-Designed cooling capacity and for a pre-designed Area of the floor. In a nut shell the builder has floors with AHUs (connected to the Chilling Unit), ready to deliver the AC to the area to be occupied. When a customer (usually from Software business) is ready/decides to occupy, along with the other services the Air-Condition works (primarily air distribution work) will be called for and this work is popularly known as LOW SIDE WORKS.